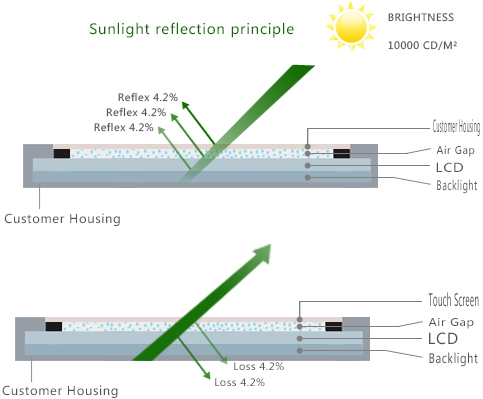

Display Principle in Sunlight – Traditional Screen

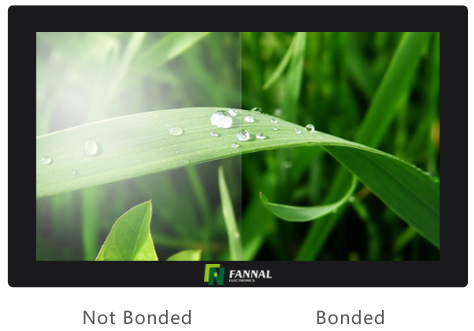

Traditional screen air bonded touch panel directly to the LCD surface. It makes an air layer between them so there are to three reflective surfaces: touch panel vs environment, touch panel vs air, LCD vs air.

If no special treatment, the reflectivity of each reflective surface to external light would come to almost 4.2%, totaled to 12.6%, 1260cd/m2 .

If the surface brightness is 1000 cd/m2 , and there are two reflective surfaces from LCD to touch panel, the final transmitted brightness is 916 cd/m2 .

If there is no special treatment, the reflectivity of each reflector to external light would come to almost 4.2%, totaled to 12.6%, 1260cd/m2 .

The useful light brightness on the display is lower than the reflected light brightness. So traditional screen is poorly readable under strong light.

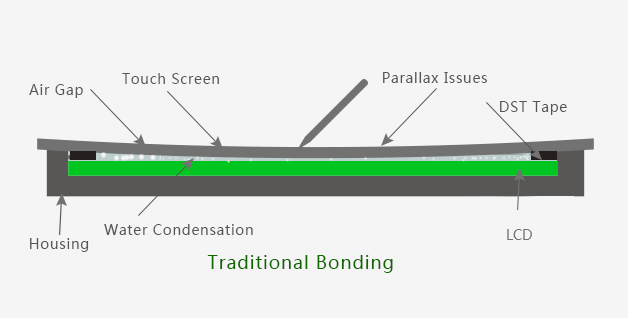

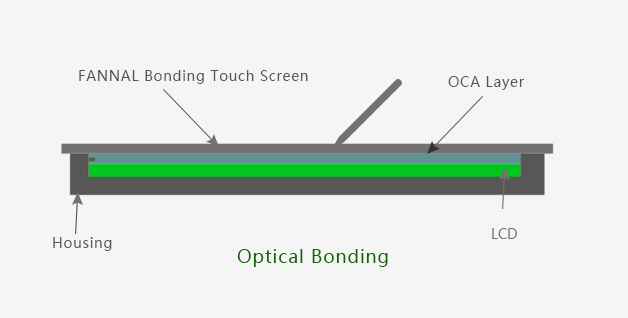

Operation Principle-Optical Bonding

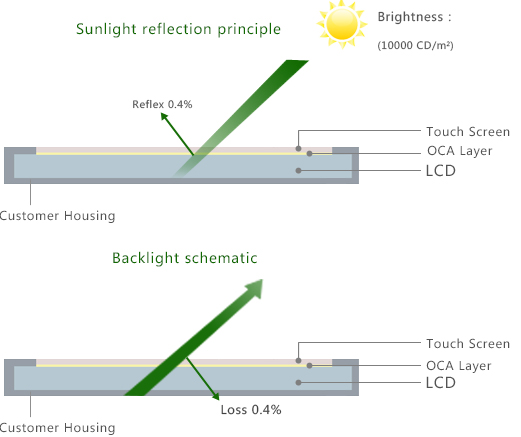

Increasing screen sunlight readability means to raise its extrinsic contrast ratio. It can be achieved by increasing LCD backlight or reducing the reflected light brightness, or both.

However, increasing the backlight, the power consumption also will rise; LCD heating will effect on its reliability. Consequently, reducing the reflected light brightness is the most effective way to tackle those problems.

Bonding touch screen or cover lens to the polarizer of LCD front side with clear optical adhesive. Since the refractive index of the optical glue is same to cover glass, both are 1.5, thus eliminating two reflective surfaces.the lower reflection, the higher contrast ratio is. Backlight 500 lumens can read in daylight; backlight 800 lumens can read under strong light.

Optical Bonding is greatly improve the sunlight readable and enhance reliability in extreme conditions

Benefits after optical bonding:

- Increase sunlight readability up to 400%

- Increase impact resistance up to 300%

- Forbid condensation and gasification

- Use in extreme conditions

- Good for slimmer design

- Resist to stains,dirt,dust,scratches

Optical bonding eliminate the gap between the touch screen and display.Comparing with traditional bonding technology,advantages will be more obvious.